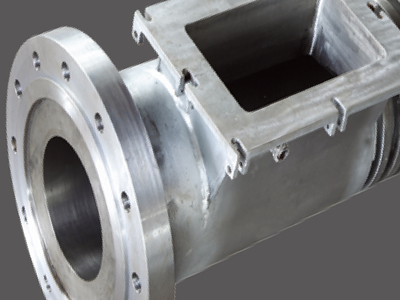

What is Screw Barrel For Recycle Pelletizing Machines?

A screw barrel, also known as an extruder barrel, is a key component of a recycle pelletizing machine. It is a cylindrical container with a screw-shaped conveyor running through its center. The screw is used to transport and mix the raw material being processed (such as plastic waste) as it moves through the barrel. The screw rotates within the barrel, causing the material to move forward, melt, and become homogenized. This continuous process helps to produce uniform pellets or granules that can be used in the manufacturing of various plastic products. The screw barrel is typically made from high-quality steel and is designed to withstand the wear and tear of the recycling process. The size, shape, and configuration of the screw barrel can affect the quality of the final pellets and can be customized for different types of materials and processing conditions.

How to choose Screw Barrel For Recycle Pelletizing Machines?

When choosing a screw barrel for a recycle pelletizing machine, there are several factors to consider, including:

1. Material Type: The type of material being processed will affect the choice of screw barrel. Different materials may have different melting points, viscosities, and abrasiveness levels, so it's important to choose a screw barrel that is suitable for the specific material being processed.

2. Screw Design: The design of the screw, including the pitch, number of flights, and flight depth, will affect the performance of the machine. A proper screw design will help ensure efficient material transport and melting, as well as the uniformity of the final pellets.

3. Screw Diameter: The diameter of the screw will impact the output capacity of the machine. A larger diameter screw will typically produce a higher output, but it will also require a larger barrel and motor.

4. Barrel Length: The length of the barrel will also impact the output capacity and processing time of the machine. A longer barrel will typically produce a higher output, but it will also require more energy to rotate the screw.

5. Surface Finish: The surface finish of the screw barrel is important to prevent material buildup and ensure uniform flow of the material. A smooth surface finish will help reduce the friction between the material and the barrel, making it easier to transport the material through the barrel.

6. Quality of the Barrel: The quality of the screw barrel will affect its durability and reliability. A high-quality barrel will typically be made from high-strength materials, have a precise and consistent surface finish, and be carefully manufactured to ensure its longevity.

7. Cost: Cost is always a consideration when choosing a screw barrel. A high-quality barrel may have a higher upfront cost, but it will likely last longer and perform better, leading to a more cost-effective solution in the long run.

It's important to choose a screw barrel that is specifically designed for the type of material being processed and the specific requirements of the recycle pelletizing machine. A well-designed and high-quality screw barrel will help ensure efficient and consistent production of high-quality pellets, leading to better productivity and profitability for the recycling operation.

EN

EN  简体中文

简体中文