What is the Bimetallic Screw Barrel?

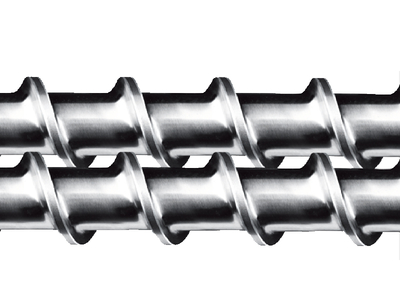

The Bimetallic Screw Barrel is a component used in the plastic processing industry, specifically in the extrusion of plastic materials. It is used in the extruder machine, which is a machine that processes raw plastic materials and converts them into finished products, such as pipes, sheets, and profiles.

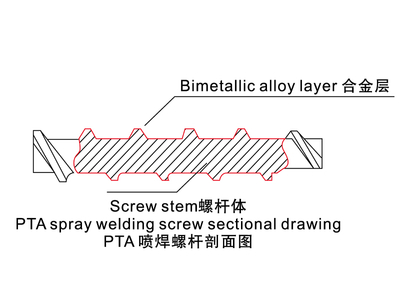

The screw barrel is an important component of the extruder because it is responsible for mixing, melting, and conveying the plastic material through the machine. The Bimetallic Screw Barrel is a specific type of screw barrel that is made from two different metals that are fused together, typically with a layer of hard-wearing, heat-resistant alloy in the center and a softer outer layer. The idea behind this is that the hard center layer provides the durability needed for high-stress applications, while the softer outer layer allows for better heat transfer.

This type of screw barrel is used in demanding applications where high temperature and abrasion resistance are required, such as when processing engineering plastics or when processing abrasive materials. Bimetallic screw barrels are designed to have a longer life span compared to traditional screw barrels, which are usually made of a single metal. This can result in reduced maintenance costs and increased production efficiency.

Application of Bimetallic Screw Barrel

Bimetallic Screw Barrels are widely used in the plastic processing industry due to their unique combination of high temperature and abrasion resistance. Some of the common applications of Bimetallic Screw Barrels include:

1. Extrusion of engineering plastics: Engineering plastics are high-performance materials that are used in demanding applications, such as automotive and aerospace parts. Bimetallic Screw Barrels are ideal for processing these materials because they can withstand high temperatures and abrasion without deforming.

2. Processing of abrasive materials: Some plastic materials contain fillers, such as glass fibers, that can be abrasive to the screw barrel. Bimetallic Screw Barrels are designed to handle these abrasive materials and can significantly extend the life of the screw barrel compared to traditional single-metal screw barrels.

3. Blown film extrusion: Blown film extrusion is a process used to produce plastic films for packaging, agricultural, and industrial applications. Bimetallic Screw Barrels are ideal for this application due to their high temperature and abrasion resistance.

4. Pipe and profile extrusion: Bimetallic Screw Barrels are also used in the production of pipes and profiles, especially those made from engineering plastics or abrasive materials. The high temperature and abrasion resistance of Bimetallic Screw Barrels make them ideal for this application.

In addition to the above applications, Bimetallic Screw Barrels are also used in other plastic processing applications, such as wire and cable insulation, sheet extrusion, and compounding. These screw barrels offer numerous benefits to plastic processors, including increased production efficiency, reduced maintenance costs, and improved product quality.

EN

EN  简体中文

简体中文