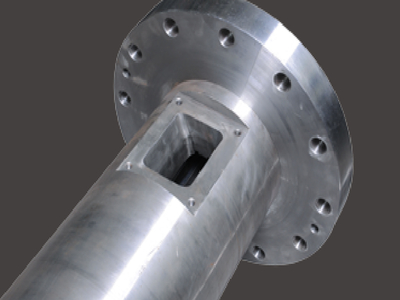

What is Screw Barrel For Fiber Chemical Equipments?

A screw barrel is a critical component in fiber chemical equipment, such as a fiber extruder or a fiber spinning machine. It is a rotating cylindrical component that helps to mix, transport, melt, and shape the fiber material being processed. The screw in the barrel has helical ridges, called flights or threads, that move the material forward as the barrel rotates. The shape, number, and depth of the threads can be adjusted to control the processing conditions and the quality of the fiber produced. The screw barrel is typically made of high-strength steel and can be treated with special coatings to resist wear and corrosion. It is a crucial component of the fiber production process and its proper functioning is essential to ensure efficient and consistent production of high-quality fiber.

How to choose Screw Barrel For Fiber Chemical Equipments?

When choosing a screw barrel for fiber chemical equipment, there are several factors to consider:

1. Material Compatibility: The screw barrel should be compatible with the material being processed and should not cause any contamination or reaction with the fiber material.

2. Screw Design: The screw design should match the specific processing requirements of the fiber material. This includes the number, shape, and depth of the threads, as well as the flight pitch and screw diameter.

3. Screw and Barrel Size: The size of the screw and barrel should be appropriate for the volume of material being processed and the desired output rate. A larger screw and barrel will handle higher volumes of material, while a smaller screw and barrel may be sufficient for lower production rates.

4. Wear Resistance: The screw barrel should be able to resist wear and maintain its dimensional stability, even under harsh processing conditions. This may require special coatings or materials that are resistant to wear and corrosion.

5. Ease of Maintenance: The screw barrel should be easy to disassemble and maintain, as regular maintenance is important for ensuring efficient and consistent fiber production.

6. Cost: The cost of the screw barrel should be considered, as well as any costs associated with maintenance and replacement.

It is important to work with a reputable supplier that has experience in the fiber production industry and can help you choose the right screw barrel for your specific needs.

EN

EN  简体中文

简体中文