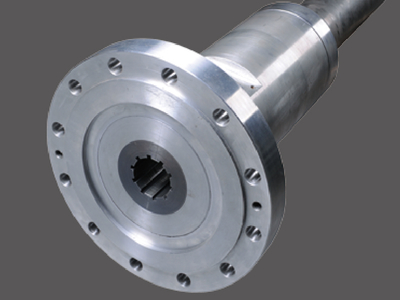

What is Screw Barrel For Blow Moulding Machines?

A screw barrel, also known as an extruder barrel, is a component of a blow molding machine that is used to melt, mix and homogenize plastic material prior to blowing it into a mold to form a desired shape. The screw barrel is made up of a screw that rotates within a cylindrical barrel, which is usually heated. The screw is designed with specific flight patterns that are intended to provide the necessary mixing and homogenization of the plastic material. The screw and barrel combination is responsible for forcing the plastic material through the barrel and into the mold. The screw barrel is a critical component of a blow molding machine and its proper operation is essential to the quality of the final product.

Characteristics of Screw Barrel For Blow Moulding Machines

The characteristics of a screw barrel for blow molding machines are:

1. Material: The screw barrel is typically made from high-quality steel, such as tool steel, nitrided steel, or stainless steel, to withstand the high temperatures and pressures involved in the blow molding process.

2. Diameter: The diameter of the screw barrel is typically in the range of 30 to 200 millimeters, depending on the size of the blow molding machine.

3. Length: The length of the screw barrel is determined by the size of the mold and the required output rate. A longer screw barrel is typically required for higher output rates, while a shorter screw barrel is sufficient for lower output rates.

4. Flight Profile: The flight profile of the screw is a key factor in determining the performance of the screw barrel. The flight profile is designed to provide the necessary mixing and homogenization of the plastic material and to prevent material degradation.

5. Heating/Cooling: The screw barrel is typically heated to maintain the plastic material in a molten state, and to prevent material degradation. Cooling is also required to control the temperature of the material and to prevent material degradation.

6. Wear Resistance: The screw barrel is subjected to high wear and tear due to the abrasive nature of the plastic material and the high temperatures involved in the blow molding process. It is important that the screw barrel is made from materials that have good wear resistance.

7. Surface Finish: The surface finish of the screw barrel is important to prevent material build-up, which can cause material degradation and reduce the performance of the screw barrel. The surface of the screw barrel should be smooth and free from rough spots or burrs.

8. Maintenance: The screw barrel requires regular maintenance to ensure that it operates efficiently and produces a consistent quality product. This includes regular cleaning, replacement of worn parts, and monitoring of the heating/cooling system.

EN

EN  简体中文

简体中文